Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

RFID Based Inventory Management System

Authors: Sri Valli Aluguri, Sahithi Maddiveni, Sri Tulasi Gayatri Kandibanda, Bhavana Kotakonda, Ms. Ch. Anusha

DOI Link: https://doi.org/10.22214/ijraset.2023.56210

Certificate: View Certificate

Abstract

An inventory management system is a software application that helps businesses efficiently manage their inventory. This project proposes the development of an inventory management system using hardware and software. The system aims to monitor the inventory levels of products in real-time and provide alerts when necessary. The system will be built using a NodeMCU (ESP8266) along with sensors such as RFID readers. Embedded C will be used to interact with the hardware and collect data from the sensors. Blynk IoT platform will be used to store inventory data and update it based on the sensor data. When the stock in the inventory is at zero, it shows a message in the app itself, along with sending an email to the given mail id. The proposed inventory management system can be useful for small businesses, warehouses, and other facilities that require real-time monitoring of inventory levels.

Introduction

I. INTRODUCTION

Inventory management is a very crucial task for any business. It involves tracking the quantity of inventory items, as well as managing the flow of inventory into and out of the business. Traditional inventory management systems are often manual and time-consuming. They can also be inaccurate, leading to stockouts and lost sales.

IoT-based inventory management systems offer a number of advantages over traditional systems. They are more efficient, accurate, and scalable. They can also be integrated with other business systems, such as enterprise resource planning (ERP) systems.

This paper presents an IoT-based inventory management system that uses RFID, NodeMCU, and Blynk IoT platform. The system is designed to be easy to use and to provide real-time inventory data. It can be used in a variety of businesses, including retail, manufacturing, and logistics.

The system consists of three main components:

- RFID Tags: The RFID tags are attached to the inventory items. They contain information about the item, such as the item ID, quantity, and location.

- NodeMCU: The NodeMCU is an IoT device that is used to read the RFID tags and to send the data to the cloud server.

- Blynk IoT Platform: The Blynk IoT platform is a cloud-based platform that is used to store the inventory data and to provide a user interface for accessing the data.

The system works as follows:

a. The RFID reader reads the RFID tags attached to the inventory items.

b. The NodeMCU sends the data read by the RFID reader to the Blynk IoT platform.

c. The Blynk IoT platform stores the data and provides a user interface for accessing the data.

The user can use the user interface to view the inventory data, such as the quantity of each item, and the last time the item was updated. The user can also use the user interface to create alerts, such as when the quantity of an item falls below a certain level.

The system is still under development, but it has the potential to revolutionize the way that inventory is managed. It is more efficient, accurate, and scalable than traditional inventory management systems. It is also easy to use and can be integrated with other business systems.

The section 1 contains Introduction about the project, section 2 contains Literature Survey, section 3 consists of proposed work, section 4 is about working of the project, section 5 shows the results and output of the project, section 6 is about conclusion and section 7 has the references for the project.

II. LITERATURE SURVEY

Inventory management system that is utilized to automatically check the tools and equipment in industrial plants and warehouses. The system utilizes radio frequency identification (RFID), a cloud database, an Android-based application program (app), and a PC-based computer program to construct a real-time raw material inventory system. RFID tags are attached to the tools and equipment and connected to a network via the Internet of Things (IoT)[1]. As part of a research program for future generation warehouses, this thesis presents an investigation into some design theories and an integrated optimization methodology for a future generation warehousing system in which an RFID-based inventory management system has the capability of interacting with a proposed RFID-enabled automated storage and retrieval mechanism without any human intervention[2].The records maintained manually will be replaced by an RFID reader and tag. The tag given to each storage unit carries the details of the stock. An RFID reader placed at the entry of the go down reads the tag[3].

The interfacing of project with NodeMCU, to measure grocery container value and see this data in the user's smartphone or pc with the help of cloud service. The warehouse stock management system is playing a significant aspect in many productions and goods-based methodology[4]. Though there are many wireless communication technologies the RFID suits the best for the warehouse stock management system. The tag data is sent from the transmitter part to the open- source hardware over a wireless link that uses the internet. The warehouse stock management system built on the architecture of the Internet of Things is developed to track the products attached to the tags with product information and their respective time stamps for further verification[5].

The IoT-based Smart Inventory Management System is an automated system designed to manage inventory efficiently using the Arduino Uno, NodeMCU, three IR sensors, Load cell sensor, Status LED, and Ultrasonic sensor. This system utilizes the concept of the Internet of Things (IoT) to provide real-time data on inventory levels, making it easier to manage and maintain inventory. The IR sensors detect the quantity of goods in the inventory, while the ultrasonic sensors are used to detect the presence and level of inventory items. The system incorporates load cell sensors to accurately measure the weight of items in inventory and convert it into quantity count by dividing the total weight by the weight of a single item[6] .

The warehouse inventory management system is playing a significant aspect in many productions and goods-based methodology. Though there are many wireless communication technologies the RFID suits the best for the warehouse inventory management system. The tag information is transferred from the transmitter section to open-source hardware via a wireless link with the aid of internet[7]. The final results of the research present the benefits, business opportunities, and challenges of IoT integration in inventory management in warehouses, which allows Vietnamese companies to better understand IoT applications and, as a result, consider deploying this technology in their warehouses. Furthermore, the findings also reveal future trends in IoT technology, which are derived from users' expectations of technological applications to express their perspectives and desires of future IoT applications toward technological organizations[8].

The high level of usability and security of this technology allows optimizing the processes of detection and location of items in an inventory system, generating great benefits such as increased productivity, decreased response times and costs. This paper shares our experience in developing and implementing and inventory system based on RFID technology[9]. The site page which is an inherent understanding to give advantageous and an interface to the client to follow the items. The created framework results in an exceptionally ease framework and works powerfully contrasted and the current present stockroom stock administration frameworks[10].

III. PROPOSED WORK

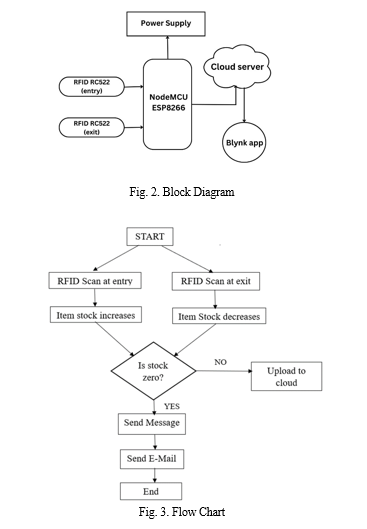

The proposed inventory management system will be built using a NodeMCU (ESP8266)[11] along with sensors such as RFID readers. Embedded C will be used to interact with the hardware and collect data from the sensors. Blynk IoT platform will be used to store inventory data and update it based on the sensor data. When the stock in the inventory goes lower than a given limit, it shows a message in the app itself.

The system will be implemented in three phases:

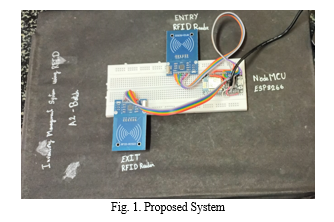

- Hardware Setup: The hardware setup will involve connecting the NodeMCU to the RFID readers and configuring the embedded C code. For this project, we’re using NodeMCU ESP8266[12] as our microcontroller and RFID RC522 for physical reading and collecting of the data. Two RFID readers are present, one being used for reading the entry of the goods into the inventory, while the other one is used for reading the exit of the goods from the inventory.

- Data Collection: The data collection phase will involve collecting data from the RFID readers and storing it in the Blynk IoT platform. All the data goes into the Blynk cloud and gets stored there. The app allows us to see the real-time readings of the stock, where we can see how many are entering the inventory and how many are leaving.

A. Modules Used

- NodeMCU ESP8266: The NodeMCU ESP8266 is an open-source platform based on the ESP8266 Wi-Fi module. It is a small, affordable, and easy-to-use microcontroller that can be used to create many IoT projects. The NodeMCU ESP8266 has a built-in Wi-Fi module that lets it connect to the internet, which makes it possible to control and monitor the NodeMCU ESP8266 remotely. This board also has several other features, including a built-in ADC, DAC, and UART. These mentioned features make the NodeMCU ESP8266 a versatile and powerful tool for IoT development in this fast-developing world.

- RFID RC522: The RFID RC522 is a 13.56 MHz RFID module that can be used to read and write RFID tags. The RFID RC522 is based on the MFRC522 chip from NXP. The MFRC522 chip supports various RFID protocols, including ISO/IEC 14443A/MIFARE, ISO/IEC 7816, and FeliCa. The RFID RC522 module can be used in a variety of applications, such as access control systems, identification systems, and inventory management.

- Blynk App: This module receives data from the Cloud server[13]. The central server module is responsible for processing data and forwarding it for analysis. It can implement threshold-based monitoring for abnormal readings. If any sensor data exceeds predefined thresholds, trigger an alert/notification mechanism. It is a popular Internet of Things (IoT) platform that allows users to build custom applications for controlling and monitoring various hardware devices and projects. It is designed to simplify the process of creating IoT applications[14], especially for those without extensive programming or electronics expertise. Users can visually design the user interface of their applications, making it accessible to a wide range of users, including hobbyists, makers, and developers.

B. Libraries Used

- SPI.H

The SPI.h library in Arduino provides functions and classes that facilitate communication using the Serial Peripheral Interface (SPI) protocol. SPI is a synchronous communication protocol commonly used to connect microcontrollers with other devices, such as sensors, displays, memory chips, and more. The SPI.h library simplifies the process of setting up and managing SPI communication in your Arduino sketches. Here are some key aspects of the SPI.h library and how it's used:

- Initialization: To use the SPI communication, you typically start by initializing the SPI interface using SPI.begin(). This sets up the necessary hardware settings for SPI communication.

- Settings Configuration: The library provides functions to configure various parameters of the SPI communication, including clock speed (SPI.setClockDivider()), data mode (SPI.setDataMode()), and bit order (SPI.setBitOrder()).

- Data Transfer: You can send and receive data over the SPI bus using the SPI.transfer() function. It sends one byte of data and simultaneously receives a byte from the connected device.

- Multiple Devices: SPI supports communication with multiple devices on the same bus using chip-select (CS) pins. You can use the SPI.beginTransaction() and SPI.endTransaction() functions to manage communication with different devices.

- Blocking vs. Non-Blocking: The SPI.transfer() function is blocking, meaning the program execution waits until the transfer is complete. Alternatively, the SPI.transfer16() and SPI.transfer32() functions allow transferring 16-bit and 32-bit data at once.

- Advanced Features: The library also provides features like bit-banging (software-based SPI), which can be useful in situations where the hardware SPI pins are already in use.

2. MFRC522.h

The line #include indicates that you're including the "MFRC522" library in your Arduino sketch. The MFRC522 library is commonly used to interface with MFRC522 RFID modules, which are widely used for reading RFID cards and tags using the SPI protocol. Here's what you can expect from using the MFRC522.h library:

- RFID Communication: The MFRC522 library simplifies the process of interacting with MFRC522 RFID modules, allowing you to read and write data to RFID cards and tags[15].

- Initialization: You'll typically initialize the RFID module in your setup () function using methods provided by the library. This involves setting up the necessary pins, configuring the module's settings, and starting communication with it.

- Reading RFID Data: The library provides functions to read the UID (unique identifier) of RFID cards and tags. You can also read and write data to the memory sectors of supported cards.

- Authentication: Certain RFID cards and tags have memory sectors that require authentication before reading or writing. The library provides methods to authenticate with these sectors using keys.

- Examples and Documentation: The library comes with example sketches that demonstrate how to use it to read RFID cards and tags. Additionally, the library documentation provides information about available methods and their usage.

3. BlynkSimpleEsp8266.h

The line #include indicates that you're including the "BlynkSimpleEsp8266" library in your Arduino sketch. The Blynk library simplifies the process of connecting Arduino-based projects to the Blynk IoT platform, enabling remote control and monitoring of your devices over the internet[16]. Here's what you can expect from using the BlynkSimpleEsp8266.h library:

- IoT Connectivity: The library provides a convenient way to connect your Arduino project to the Blynk cloud platform. With Blynk, you can create a mobile app or web interface to control and visualize your connected devices.

- Initialization: You'll typically initialize the Blynk library and establish a connection to the Blynk server in your setup () function using the Blynk. Begin (auth, ssid, pass) function, where auth is your Blynk authentication token, and ssid and pass are the credentials for your Wi-Fi network.

- Widgets and Virtual Pins: Blynk uses "widgets" to interact with your devices. You can create buttons, sliders, graphs, and other UI elements in the Blynk app. These widgets communicate with your Arduino code using "virtual pins."

- Blynk.run (): To maintain the Blynk connection and handle incoming commands from the app, you need to call Blynk.run () periodically within your loop () function.

- Widget Callbacks: You can define callback functions to be executed when a widget in the Blynk app is interacted with. These callbacks allow you to respond to user input.

- Syncing Data: Blynk allows you to push data from your device to the app and pull data from the app to your device. You can update widget values and properties dynamically.

4. ESP8266WiFi.h

The line #include indicates that you're including the "ESP8266WiFi" library in your Arduino sketch[17]. The ESP8266WiFi library provides functions and classes for configuring and connecting to Wi-Fi networks using the ESP8266 module. The ESP8266 is a popular Wi-Fi module that can be used as a standalone microcontroller or as an add-on to other microcontrollers like Arduino. Here's what you can expect from using the ESP8266WiFi.h library:

- Wi-Fi Connectivity: The library allows you to configure and manage Wi-Fi connections on the ESP8266 module. This is essential for connecting your device to the internet and communicating with other devices or services.

- Initialization: You'll typically initialize the Wi-Fi module in your setup () function using methods provided by the library. This involves connecting to a Wi-Fi network by providing the SSID (network name) and password.

- Status and Information: The library provides functions to check the Wi-Fi status (WIFI. Status ()), get the local IP address (WiFi.localIP()), and retrieve other network-related information.

- Configuring Wi-Fi Credentials: Some sketches might include mechanisms for users to input Wi-Fi credentials (like SSID and password) through a web server running on the ESP8266. This way, the device can be reconfigured without reprogramming.

- Handling Wi-Fi Disconnects: You can use the library to handle disconnects and automatically reconnect in case the connection is lost.

IV. WORKING

In An inventory management system using RFID (Radio Frequency Identification) and ESP8266 is a modern and the efficient approach to track and manage inventory in the real-time.

Each product/item in the inventory is equipped with an RFID tag containing a unique identifier. An RFID reader is connected to the ESP8266, which reads the RFID tags' unique identifiers. It acts as the microcontroller to interface with the RFID reader and communicate with the central database or server. This is the central storage that maintains the inventory data and keeps track of the item's location and status. Every product in the inventory is assigned an RFID tag.

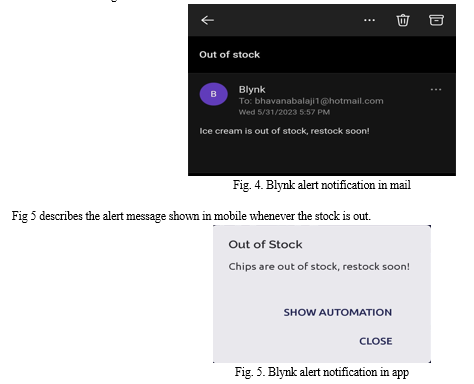

When a product enters or leaves the inventory space, the RFID reader detects the unique identifier of the RFID tag associated with the product and increases the count or decreases the stock level in blynk. The ESP8266 microcontroller receives the RFID tag's unique identifier from the RFID reader and processes the data. The ESP8266 connects to the central database or server via Wi-Fi or other communication protocols. It sends the RFID tag's unique identifier to the blynk.

The blynk receives the unique identifier and processes it. The database contains information about each product, such as its name and quantity of the product. The blynk updates the inventory record based on the received RFID tag data. It tracks the movement of items in real-time, updating the status of each product accordingly.

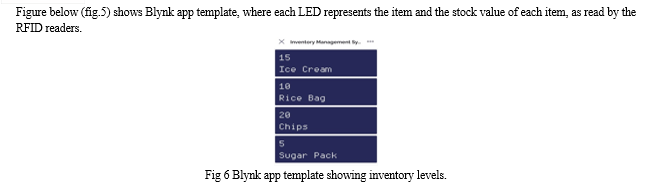

Users can access the inventory management software, which interfaces with the Blynk. The Blynk provides a user-friendly interface to view and manage the inventory. It allows users to perform tasks like adding new items, updating quantities, and generating reports. The inventory management system can provide real-time monitoring of inventory levels, allowing businesses to optimize stock levels and prevent stockouts. It can also send alerts if there are discrepancies or if certain items require attention.

The system can generate various reports and analytics, such as inventory levels, item movement history and more. These reports help businesses make informed decisions regarding inventory management and optimize their operations.

Overall, the integration of RFID technology with the ESP8266 microcontroller allows for efficient and accurate inventory management, reducing manual labor and improving inventory control and accuracy.

V. RESULTS AND DISCUSSIONS

The aim of this project is to build an inventory management system at a small scale, mainly to help out the small-scale businesses and warehouses that do not need large, automated monitoring system for inventories yet can’t be used with conventional methods. All these readings are then pushed to cloud, that note down the values of the inventory based on the readings from the RFID readers. This reader then sends the data to the Blynk cloud, and is read through the Blynk app. An alert notification is pushed to the user when the stock levels fall down to zero. The RFID system has resulted in significant labor and time savings. Previously, it took an average of 3 hours per day for our employees to conduct manual inventory counts. With RFID, this process now takes less than 30 minutes. This reduction in labor has allowed our employees to focus on more value-added tasks. RFID technology has substantially reduced human errors in inventory management. Prior to RFID, we frequently encountered data entry errors and mislabeled items. With RFID, these errors have become rare, contributing to higher data accuracy and reduced operational disruptions. Our inventory security procedures were greatly improved by the RFID system. The ability to monitor product movement in real time contributed to a decrease in theft and unlawful access to restricted inventory regions. Comparing RFID technology to more conventional techniques like barcode scanning or manual counts, it dramatically improves inventory accuracy. As a result, stock level errors decrease and inventory management as a whole improves. RFID tags can be scanned rapidly and precisely, making it possible to follow inventory movements in real time. This lowers the possibility of stockouts or overstocking and helps firms stay informed about stock levels. Fig. 4 describes notification of out of stock in mail.

Conclusion

In conclusion, this paper has presented the design and implementation of an IoT-based inventory management system, using RFID. The system uses RFID tags and readers to track the movement of inventory items and to provide real-time inventory data. The system can be used in a variety of businesses, including retail, manufacturing, and logistics. The system is still under development, but it has the potential to revolutionize the way that inventory is managed. It is more efficient, accurate, and scalable than traditional inventory management systems. It is also easy to use and can be integrated with other business systems. The system was implemented using a NodeMCU (ESP8266) along with sensors such as RFID readers. Embedded C was used to interact with the hardware and collect data from the sensors. Blynk IoT platform was used to store inventory data and update it based on the sensor data. When the stock in the inventory goes lower than a given limit, it shows a message in the app itself. The system was tested in a small-scale business, and it was found to be effective in tracking inventory levels and providing real-time data. The system is still under development, but it has the potential to be a valuable tool for businesses of all sizes.

References

[1] M. C. Chen, Y. T. Cheng, and C. Y. Siang, “Development of Inventory Management System Based on Radio Frequency Identification Technology,” Sensors and Materials, vol. 34, no. 3, pp. 1163–1177, 2022, doi: 10.18494/SAM3497. [2] S. Al-Yahya, “Integration and Optimisation of an RFID-Enabled Inventory Management System of a Future Generation Warehousing System Thesis for the Degree of Doctor of Philosophy,” 2017. [3] C. Joji Babu, M. Pradeep, K. Sai Divya, K. Hima Sri, and A. Professor, “Issue 3 www.jetir.org (ISSN-2349-5162),” 2019. [Online]. Available: www.jetir.org [4] B. Nagaria, P. Shroff, and R. Mehrotra, “IoT Based Inventory System for Stock Management,” International Research Journal of Engineering and Technology, vol. 4094, 2008, [Online]. Available: http://mystocks.cf [5] A. Daftarband, M. Shaikh, P. B. B. Waghmode, and B. T. Students, “Stock Management Using IOT,” 2022. [Online]. Available: www.ijrpr.com [6] S. Prabakaran, V. Shangamithra, G. Sowmiya, and R. Suruthi, “Advanced Smart Inventory Management System Using IoT,” 2023. [Online]. Available: www.ijcrt.org [7] B. S. S. Tejesh and S. Neeraja, “Warehouse inventory management system using IoT and open-source framework,” Alexandria Engineering Journal, vol. 57, no. 4, pp. 3817–3823, Dec. 2018, doi: 10.1016/j.aej.2018.02.003. [8] T. Nguyen, “The Impact of the Internet of Things (IoT) on Inventory Management in Warehouses.” [9] F. Gualoto Suárez, G. Ñ. Caiza, S. G. Yoo, and E. Sangolquí, “Stock Management System Using RFID and Geolocation Technologies,” 2017. [Online]. Available: http://www.ripublication.com [10] V. Bakyalakshmi, M. Anithamary, R. Bharathy, and U. Jhanani Shree, “Systematized Warehouse Based on IoT,” in Journal of Physics: Conference Series, IOP Publishing Ltd, Mar. 2021. doi: 10.1088/1742-6596/1818/1/012226. [11] A. Jaathya, A. L. Reddy, G. Nikhitha, and C. Anusha, “Implementation Of Vehicle Theft Detection and Identification System,” 2022. [Online]. Available: www.irjet.net [12] S. Medhavath, M. Modium, P. Pasula, D. Begari, and A. G. Chilupuri Narayanamma, “FACE RECOGNITION BASED ATTENDANCE SYSTEM USING ESP 32CAM,” 2022. [Online]. Available: http://www.ijeast.com [13] C. Anusha, “Automation in Wireless Control System: A Small Review Study of Automation of Water Motor using ZigBee,” Int J Res Appl Sci Eng Technol, vol. 6, no. 4, pp. 512–514, Apr. 2018, doi: 10.22214/ijraset.2018.4089. [14] C. Anusha, “Design of Single Legged Hopper Robot in Gazebo,” Int J Res Appl Sci Eng Technol, vol. 11, no. 6, pp. 3752–3759, Jun. 2023, doi: 10.22214/ijraset.2023.54189. [15] C. Anusha and N. K. Jyothi, “A NOVEL NON-INVASIVE MEASUREMENT OF ENDOSPERM IN TENDER COCONUT USING MICROWAVES,” 2021. [Online]. Available: http://www.ijeast.com [16] C. Anusha and K. Jyothi, “AN ARTIFICIAL INTELLIGENCE-BASED SPEAKING SYSTEM FOR DUMB PEOPLE,” 2022. [Online]. Available: http://www.ijeast.com [17] C. Anusha and K. Reddy, “Automation in Wireless Control System: A Small Review Study of Automation of Water Motor using ZigBee,” 2018. [Online]. Available: www.ijraset.com512

Copyright

Copyright © 2023 Sri Valli Aluguri, Sahithi Maddiveni, Sri Tulasi Gayatri Kandibanda, Bhavana Kotakonda, Ms. Ch. Anusha. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56210

Publish Date : 2023-10-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online